PVC coated razor wire is a high-security barrier designed to upgrade perimeter protection for military bases, borders, airports, prisons, industrial facilities, and residential compounds. It features a high-tensile galvanized steel core wrapped with a durable PVC coating, providing outstanding corrosion resistance and extended service life in harsh, coastal, or humid environments.

This product can be installed with chain link fence, welded mesh fence, defensive barriers, or mounted directly on walls and gates, making it one of the most widely used modern security materials.

What is PVC Coated Razor Wire?

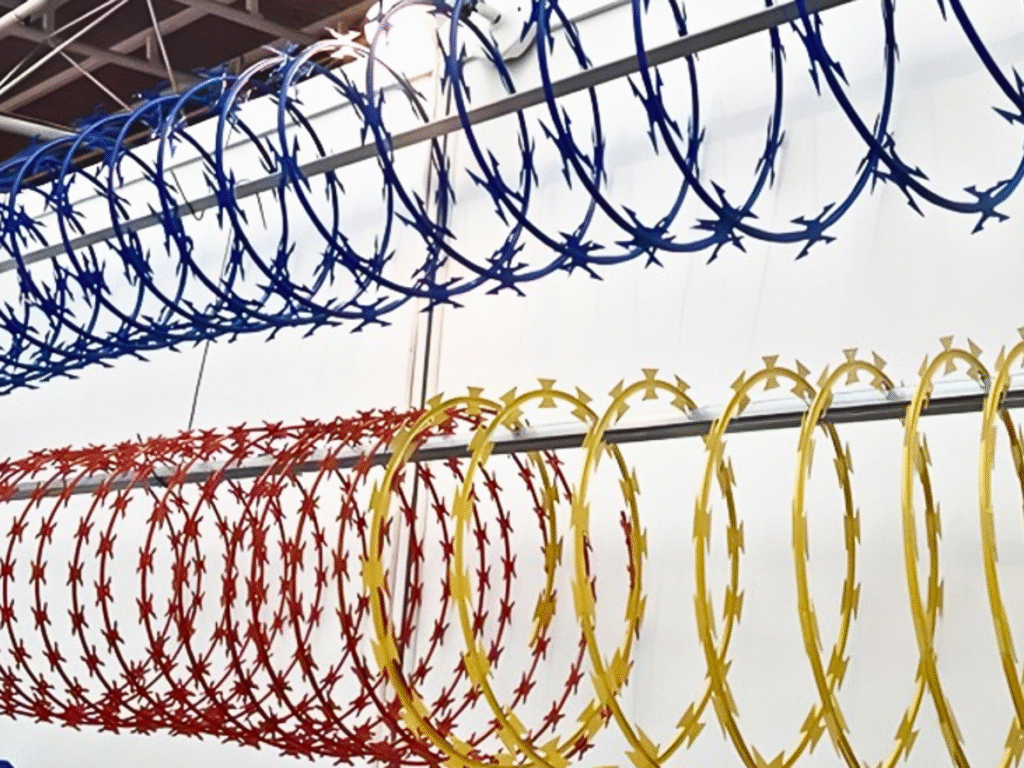

PVC coated razor wire combines sharp steel blades with a coated steel wire core to form a long-lasting security barrier. The PVC layer protects the metal from water, chemicals, and UV exposure, significantly improving its lifespan compared with standard galvanized razor wire. Available in green, black, grey, olive, and custom colors to match environment or camouflage use.

Product Features

- Enhanced corrosion resistance with PVC coating for harsh environments

- High tensile strength wire prevents cutting and forceful intrusion

- Bright colors available (green, black, grey) for visibility and aesthetics

- Longer lifespan compared to standard hot-dip galvanized razor wire

- Easy installation on fences, walls, and security barriers

- Better visibility for CCTV surveillance

- Weatherproof & UV-resistant

Razor Wire Types by GABION-S™

PVC-coated finish for enhanced durability, weather protection, and cleaner appearance.

The most widely used design, expanding into a three-dimensional barrier. Available in single coil, double coil, and cross-type structures.

Razor wires welded into rigid mesh panels, commonly used for airports, government facilities, and high-security warehouses.

Specification of Razor Wire

Core Wire Material

| Type | Material | Tensile Strength |

|---|---|---|

| Standard | Hot-dip galvanized steel | 350–550 N/mm² |

| High-tensile | Heavy zinc steel wire | 800–1200 N/mm² |

PVC Coating Options

| Coating Type | Thickness | Color |

|---|---|---|

| Standard PVC | 0.4–0.6 mm | Green, Black, Grey |

| Heavy PVC | 0.8–1.0 mm | Military Green, Olive |

Coil Specifications

| Diameter | Loops | Expanded Length | Remarks |

|---|---|---|---|

| 450 mm | 56 | 8–10 m | Light-duty |

| 600 mm | 56 | 10–12 m | Standard security |

| 730 mm | 56/72 | 12–15 m | Airports & borders |

| 900 mm | 72 | 15–18 m | High-risk zones |

Blade Types

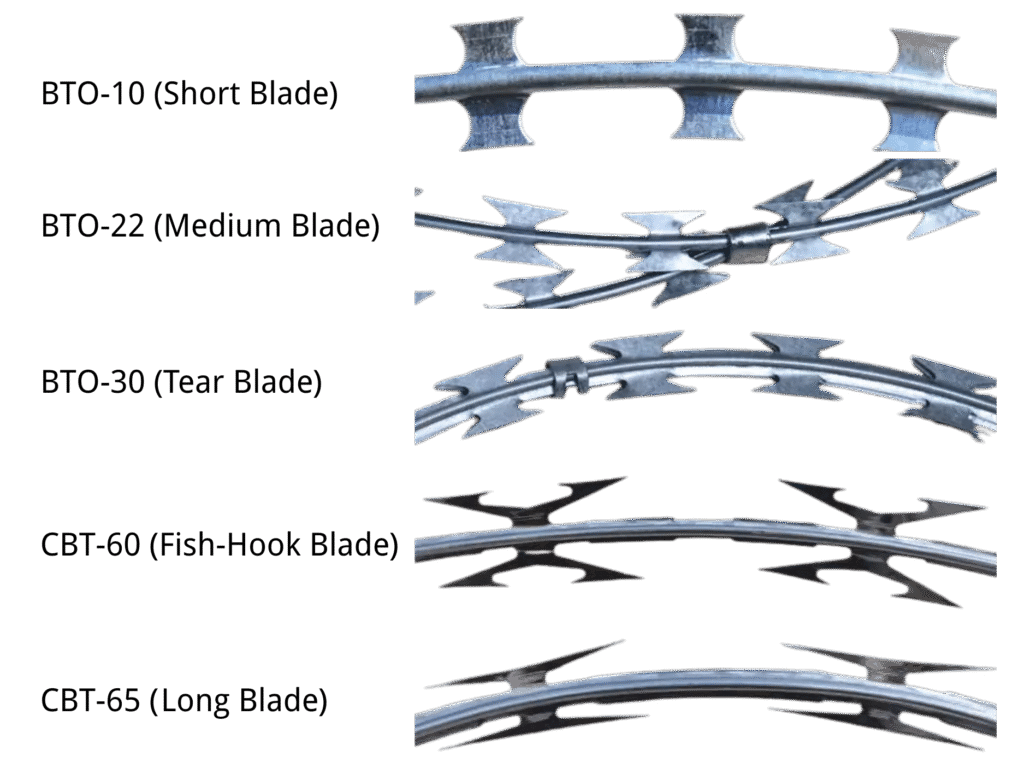

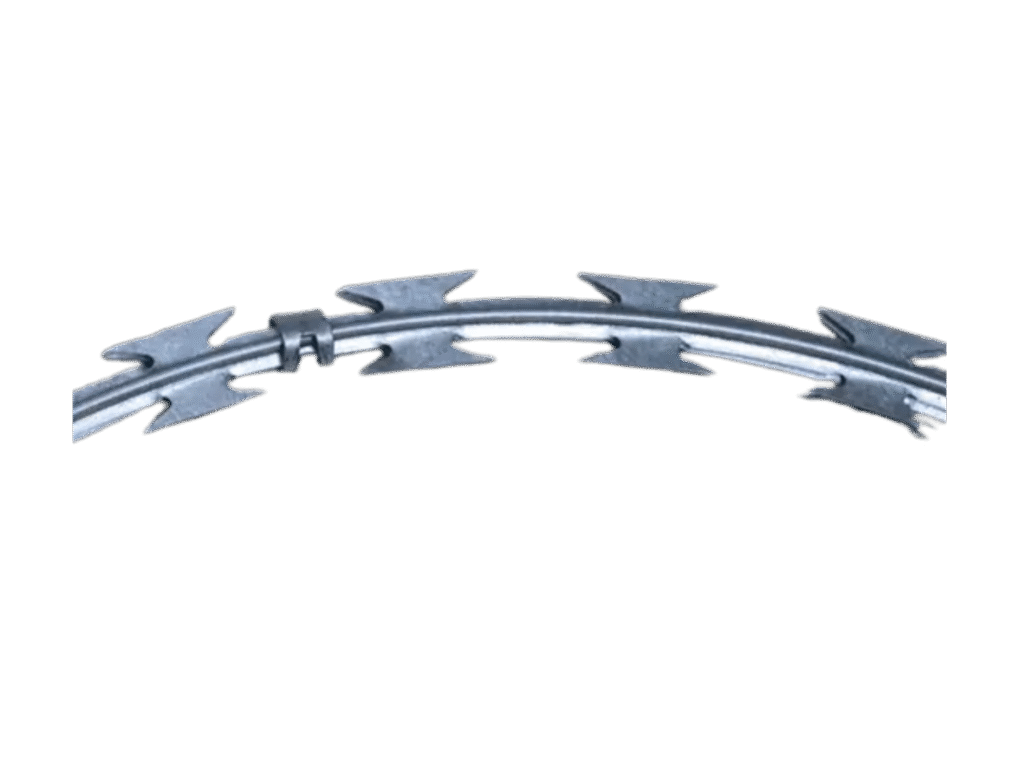

The blade profiles of razor wire are mainly classified into BTO (Barbed Tape Obstacle) and CBT (Concertina Barbed Tape) series. Among them, the five most widely used types are: BTO-10, BTO-22, BTO-30, CBT-60, and CBT-65 — covering short, medium, long, and special security blade designs.

| Specification | BTO-10 (Short Blade) | BTO-22 (Medium Blade) | BTO-30 (Tear Blade) | CBT-60 (Fish-Hook Blade) | CBT-65 (Long Blade) |

|---|---|---|---|---|---|

| Blade Type | BTO-10 | BTO-22 | BTO-30 | CBT-60 | CBT-65 |

| Barb Thickness | 0.50 ± 0.05 mm | 0.50 ± 0.05 mm | 0.50 ± 0.05 mm | 0.50 ± 0.05 mm | 0.50 ± 0.05 mm |

| Barb Length | 10 ± 1 mm | 22 ± 1 mm | 30 ± 1 mm | 60 ± 2 mm | 65 ± 1 mm |

| Barb Width | 13 ± 1 mm | 16 ± 1 mm | 18 ± 1 mm | 31 ± 1 mm | 51 ± 1 mm |

| Barb Spacing | 25 ± 2 mm | 35 ± 2 mm | 45 ± 2 mm | 100 ± 2 mm | 100 ± 2 mm |

| Core Wire Diameter | 2.5 ± 0.1 mm | 2.5 ± 0.1 mm | 2.5 ± 0.1 mm | 2.5 ± 0.1 mm | 2.5 ± 0.1 mm |

| Security Level | ★★☆☆☆ | ★★★☆☆ | ★★★★☆ | ★★★★★ | ★★★★★ |

| Cost Level | ★ | ★★ | ★★★ | ★★★★ | ★★★★ |

| Typical Applications | Low-cost fencing, basic perimeter | Industrial & commercial fencing | Medium–high security zones | Military, sensitive facilities | Prisons, top-tier security zones |

Razor Wire Applications

Border security

Production & Delivery Process

When you work with GABION-S™, you receive fast-response wire solutions, stable mass-production capacity, and dependable global delivery. Our workflow is designed for efficiency and transparency, ensuring your orders are completed on time.

Once we receive your requirements, our technical team will respond within 6–12 hours with complete razor wire options, specifications, and solutions.

All product details—such as blade type, coil size, packaging, and material—will be provided clearly and quickly.

Step 1: Specification Confirmation (6–12 Hours)

To ensure accuracy, you can confirm your order through:

- Razor wire samples

- Online video verification of the production process.

This confirmation stage typically takes 1–2 days.

Step 2: Production Plan & Sample Verification (1–2 Days)

Step 3: Mass Production (10–15 Days)

Once your order is confirmed, full-scale production begins immediately.

With our advanced manufacturing lines and stable output capacity, most razor wire orders are completed within 10–15 days.

Step 4: Packing, Loading & Shipping (2–10 Days)

GABION-S™ offers multiple package options, including:

- Coils with handles, Moisture-proof wrapping

- Custom-branded packaging for distributors and wholesalers

Installation Options

- Installed on chain link fence

- Mounted on welded mesh fence

- Fixed on concrete/brick walls

- Integrated with security defensive barriers

- Combined with electric fence systems

Why Choose GABION-S™

- China’s No.1 expert in defensive barrier & wire mesh solutions

- Large-scale production ensures stable supply and fast delivery

- Strict quality control from raw wire to finished coil

- Custom colors, packaging, blade types, and coil diameters

- Export-ready packaging for global shipment

FAQ

Q1: Does PVC coated razor wire last longer than galvanized?

Yes. It offers 2–3× longer service life in humid or coastal environments.

Q2: Is it suitable for residential use?

Yes. The colored PVC coating gives a cleaner, more integrated appearance.

Q3: What is the best blade type?

BTO-22 is the most widely used for cost and performance balance.