What is Stainless Steel Razor Wire?

Stainless Steel Razor Wire is a high-security fencing material designed for long-term outdoor protection. With excellent corrosion resistance, sharp cutting blades, and long service life, stainless steel razor wire is widely used in military bases, airports, prisons, industrial facilities, and residential perimeter security. Compared with galvanized razor wire, stainless steel grades such as SS304 and SS316 offer superior durability, especially in coastal or highly corrosive environments.

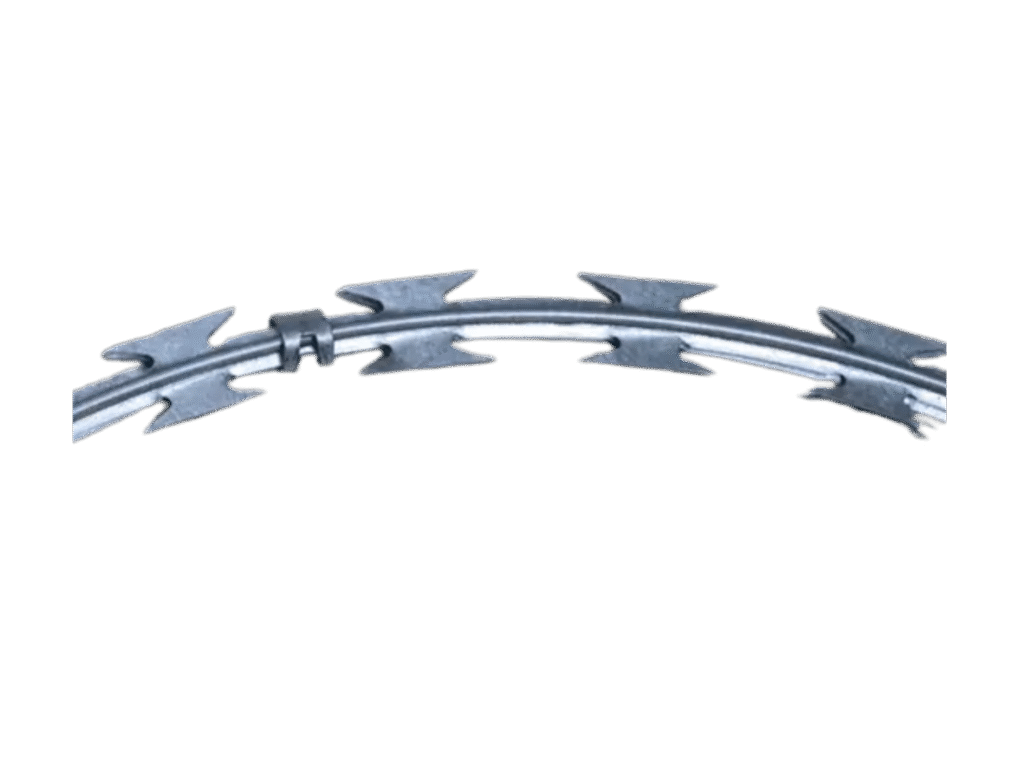

Stainless steel razor wire is made of stainless steel sheet stamped into razor-sharp blades and wrapped around a high-tensile stainless steel core wire. The blades provide strong deterrence, while the durable steel core ensures high tensile strength and long-lasting performance. Stainless razor wire maintains its strength and appearance even after years of exposure to rain, sun, humidity, and chemicals.

Product Features

- Superior Corrosion Resistance:Long service life, no rusting.

- High Security Protection:Sharp blades provide strong deterrence.

- Low Maintenance:Stainless steel requires minimal upkeep.

- Environmentally Friendly:No chemical coatings, fully recyclable.

- Stable Structure:High-tensile core wire ensures durability and stability.

Types of Razor Wire

The blade profiles of razor wire are mainly classified into BTO (Barbed Tape Obstacle) and CBT (Concertina Barbed Tape) series. Among them, the five most widely used types are: BTO-10, BTO-22, BTO-30, CBT-60, and CBT-65 — covering short, medium, long, and special security blade designs.

Single Coil Razor Wire

A cost-effective option for perimeter fencing. Easy to install and suitable for walls, fences, and building roofs.

Concertina Razor Wire

Features accordion-style loops that expand to form a barrier wall. Available in small, medium, and large diameters (300–1000mm).

Flat Wrap Razor Wire

Designed for urban and limited-space areas. Provides strong security without excessive outward expansion.

Specification of Stainless Steel Razor Wire

| Item | Data |

|---|---|

| Material | SS304 / SS316 |

| Core Wire Diameter | 2.5mm ± 0.1mm |

| Blade Thickness | 0.5–0.6mm |

| Coil Diameter | 300–1000mm |

| Blade Types | BTO-10, BTO-12, BTO-22, CBT-65 |

| Tensile Strength | 900–1200 MPa |

| Coating | Natural stainless steel, no rust |

Key Advantages

- Maximum security and deterrence with aggressive blade design

- Extended service life thanks to anti-corrosion coatings

- Cost-effective protection with minimal maintenance requirements

- Flexible installation on walls, fences, concrete barriers, and metal posts

- Customizable configurations to match different security levels and project needs

Applications of Stainless steel Razor Wire

Stainless steel razor wire is widely used in various high-security environments. It can be installed on top of chain link fences, welded mesh fences, field fences, concrete walls, and gates. Stainless steel concertina wire often cooperates with these fencing systems to form an enhanced protective barrier. It significantly upgrades the overall security level and effectively protects your property, facilities, and family from potential threats or intrusions.

Typical applications include:

- Airports & seaports

- Military and border security

- Industrial plants and warehouses

- Residential perimeter security

- Oil, gas, and utility stations

- Farms and private land protection

Production & Delivery Process

When you work with GABION-S™, you receive fast-response wire solutions, stable mass-production capacity, and dependable global delivery. Our workflow is designed for efficiency and transparency, ensuring your orders are completed on time.

Once we receive your requirements, our technical team will respond within 6–12 hours with complete razor wire options, specifications, and solutions.

All product details—such as blade type, coil size, packaging, and material—will be provided clearly and quickly.

Step 1: Specification Confirmation (6–12 Hours)

To ensure accuracy, you can confirm your order through:

- Razor wire samples

- Online video verification of the production process.

This confirmation stage typically takes 1–2 days.

Step 2: Production Plan & Sample Verification (1–2 Days)

Step 3: Mass Production (10–15 Days)

Once your order is confirmed, full-scale production begins immediately.

With our advanced manufacturing lines and stable output capacity, most razor wire orders are completed within 10–15 days.

Step 4: Packing, Loading & Shipping (2–10 Days)

GABION-S™ offers multiple package options, including:

- Coils with handles, Moisture-proof wrapping

- Custom-branded packaging for distributors and wholesalers

Why GABION-S™?

- Professional razor wire manufacturing with strict quality control

- Material traceability and stainless steel grade certificates

- Fast production, stable supply, global shipping

- Customized coil diameter, blade type, packaging, and installation support